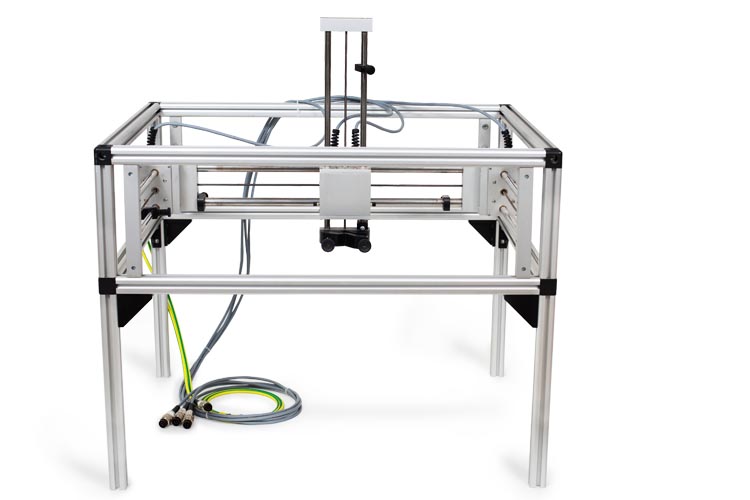

Article No. VK-62000

Positioning system

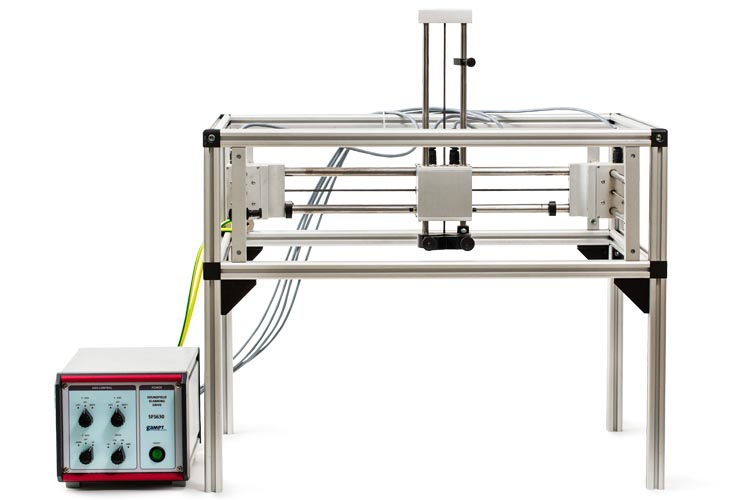

Motorized 3-axis positioning system for hydrophones and sensors

The sound field geometry, i.e., the position and size of the focus, the aperture angle of the beam, and the intensity distribution along different directions of sound propagation, is particularly important for assessing the quality of ultrasound probes. The precise measurement of ultrasonic fields is just as important for the development of high-resolution diagnostic ultrasound B-mode imaging systems as it is for determining the maximum intensity of high-intensity therapeutic ultrasound devices (HIFU) used in cancer treatment. The sound fields are measured by point scanning using suitable sensors (membrane hydrophone, HIFU hydrophone, thermoacoustic sensor). For the targeted positioning of the sensor in the sound field, GAMPT has developed a positioning system that can be used to determine the intensities at defined points along different lines, areas, or volume ranges.

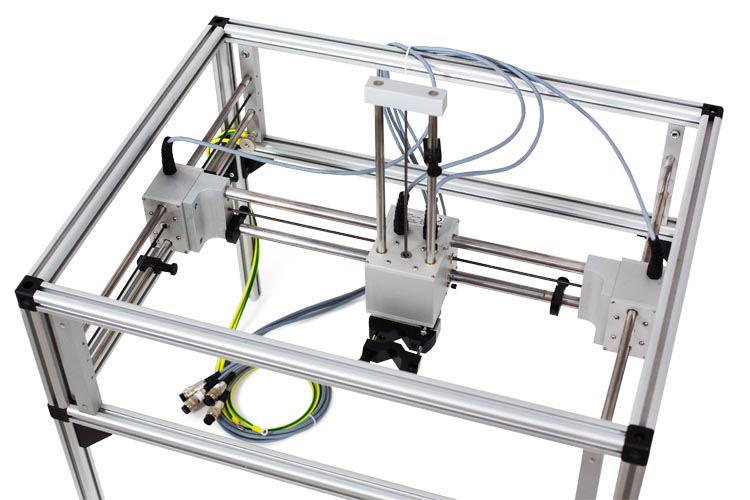

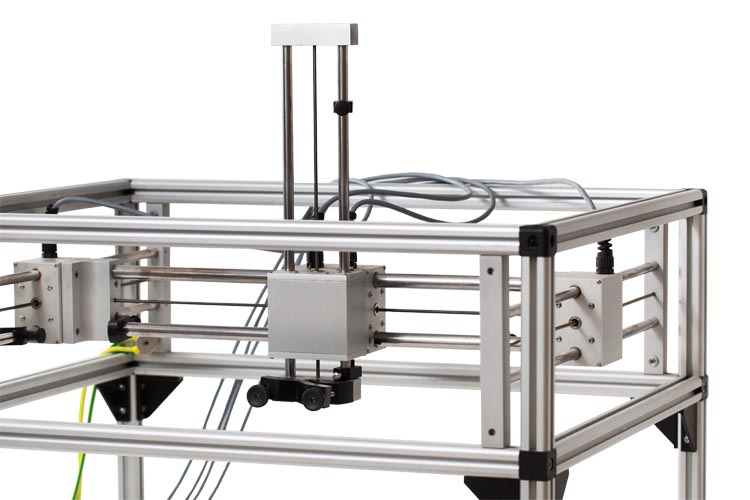

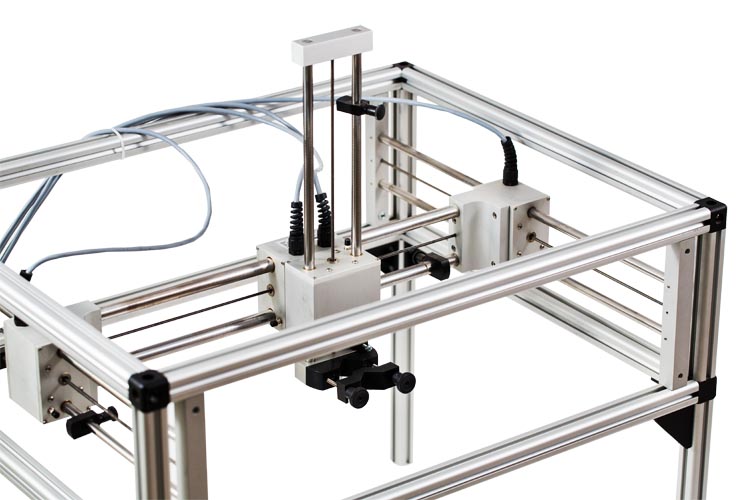

The axes of the positioning system are driven by integrated stepper motors and a control unit. Each axis is equipped with two freely positionable limit switches.

Each axis can be positioned individually at four different speeds via the control unit. This enables both fast coarse positioning and fine adjustment, e.g., in the focus of a sound source, by hand.

A universal holder with prism clamping jaws is available for mounting the measuring sensors (hydrophone, etc.) or the ultrasonic probe. This allows the measuring sensors to be mounted directly or additional tripod mounts to be attached. Alternatively, various mounts are available for fixing the hydrophone or thermal probe, so that the ultrasonic probe can be clamped into the scanner and moved.

The control unit for controlling the stepper motors can be connected to a PC via USB. Using the software supplied, the axes can be positioned at any speed or freely definable areas can be scanned with a location resolution specified by the user. The measured values can be recorded using the HC100 hydrophone controller from GAMPT or an oscilloscope.

The positioning system is primarily used to visualize the field geometry of an ultrasound probe. Especially in the case of highly complex ultrasound sensors with dynamic focusing, such as those used in modern ultrasound diagnostics, measuring the exact intensity distribution is an indispensable tool in sensor development and performance evaluation. Above all, finding and measuring local intensity maxima, which are of enormous importance for patient safety in ultrasound devices, would be difficult to imagine without suitable scanning equipment. Last but not least, the legal obligation to comply with and declare the limit value parameters in accordance with IEC 60601 for ultrasound probes requires the use of a positioning system for sound field analysis.

In addition, the positioning system can also be used for high-resolution scanning of material samples or other test objects, for example in the field of non-destructive testing or printed circuit board analysis. A suitable measuring tank and other accessories or customized solutions are also available on request.

| Dimensions: | length 650 mm depth 520 mm hight 520 mm |

| Scan path: | x direction 300 mm y direction 350 mm z direction 200 mm |

| Scan speed: | maximal 20 mm/s |

| Postion accuracy: | 0.01 mm |

Delivery includes ground cable.